FLAMINGO ADDITIVES AND COLOURTS LLP

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FLAMINGO ADDITIVES AND COLOURTS LLP

Additive Masterbatches

Description / Specification of Additive Masterbatches

We are involved in offering a wide range of Additive Masterbatches to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Additive Masterbatches. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Electrically Conductive Plastics

Premix OY Finland is world leaders in conductive and dissipative range of compounded polymer. These polymers find application in

• Extruded sheets & profiles for corrugated sheets, boxes & trays for assembly & packaging of electronic products.

• Blown films for packing of electrical sensitive chips, circuit boards, sensors.

• Injection molded products such as trays & bins for electric & electrical industry, nozzle boots for fuel dispensing pumps, outer covers & panel for electronic equipments .

• Blow molded tubes for fuel pipes in auto mobiles.

• Conductive bags & liners for packaging of hazardous & explosive chemicals.

Shut Off Nozzle

Shut-off nozzles are used exclusively for injection moulding processing and are often an essential component of the machine. Installed at the crucial interface between heated injection unit and cooled mould, the nozzle is the gateway which regulates the melt flow while bearing the entire contact force of the machine.

Shut-off nozzles were originally developed in the 1960’s to prevent melt drooling from the nozzle orifice once the injection unit pulled back from the cold mould after injection. This not only prevented loss of material but also reduced process breakdowns. Even today shut-off nozzles can still be used for this purpose but of course the advantages of using them have increased considerably since those times. Nowadays the primary functions of the shut-off nozzle include;

• Reducing cycle times by dosing the next shot regardless of whether the mould is open or if the injection unit is retracted.

Static Mixer

Profound market experience and latest fluid dynamic simulation technology was the basis for the development of the new Promix Melt Blender SMB plus. The new flow optimized mixer design (patent pending) combines high mixing performance with lowest pressure drop. The strong structure gives maximum safety during operation. Excellent inline cleaning possibilities allow fast color changes. The open structure supports cleaning and inspection of the dismantled mixer. The mixer is normally installed directly before the die, after the screen changer and melt pump.

Recycle Polymer

Ecoblue manufactures near-virgin quality & specialty grade PP and PET chips from industrial waste.

Unique Features:

• Economical

• Excellent metallic effect, Masterbatch cost is eliminated.

• Consistent quality due to in-house production.

• Mechanical properties comparable to virgin homopolymer PP.

Germ Guard Tm

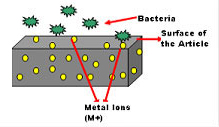

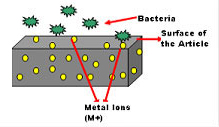

How does GermGuard works?

GermGuardTM uses precious metal nanoparticles in its product to attack the microbes. The product prepared using Germ Guard TM technology gives permanent antimicrobial activity.

Metal nanoparticles when comes in contact with the bacteria penetrates the cell wall, punctures the protoplasm and hence destroys its metabolism.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.